Competency

We are already supplying approx. over 4 million components per annum using above processes

BELOW IN RESOURCES LINKED WITH ABOVE

Extrusion: – Extrusion is a compression process in which the work material is forced to flow through a die opening to produce a desired cross-sectional shape called an Extrusion process.

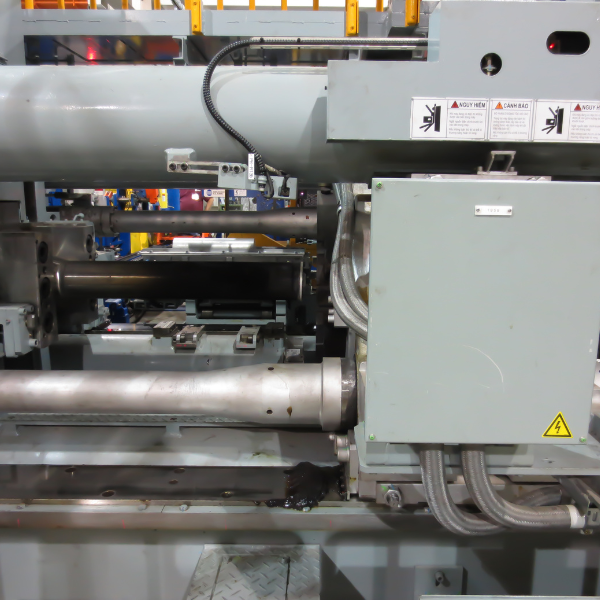

Die casting:- Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts with a high quality finish. Its ability to produce detailed parts makes it perfect for the mass production of products. Die castings are made from non-ferrous metals such as zinc, copper, aluminum, magnesium, lead, pewter, and tin.

FORGING:- Forging is a manufacturing process involving the shaping of metal through hammering, pressing, or rolling. These compressive forces are delivered with a hammer or die. Forging is often categorized according to the temperature at which it is performed cold, warm, or hot forging.

CNC:- CNC, or Computer Numerical Control, encompasses the manufacturing process where machines cut, carve and form parts based on computer codes that control the cutting tool’s speed and movement.

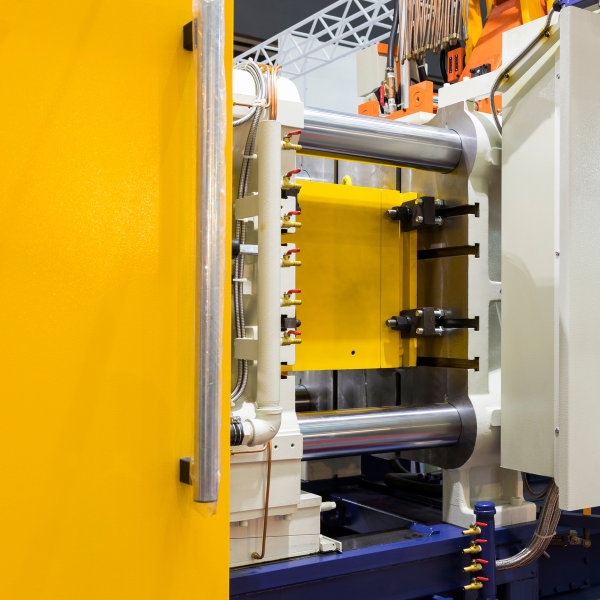

Injection moulding:- Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers.

Sheet Metal stamping:- The technical definition of metal stamping is that it’s a type of cold forming process that uses extreme force and/or speed to permanently alter the shape of a piece of metal. For sheet metal stamping, the work piece is sheet metal. However, metal stamping machines can be used for metal wires and other metal forms as well.